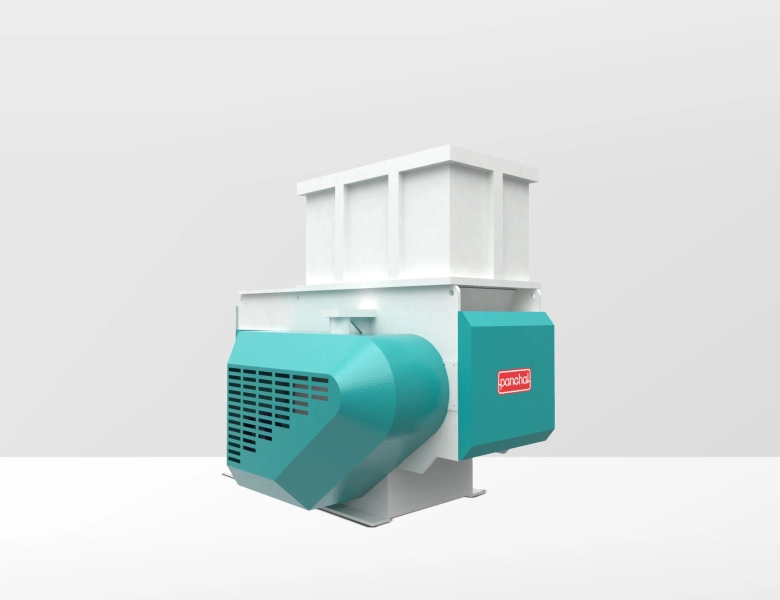

Panchal Plastic Machinery Pvt. Ltd is a leading manufacturer of Single Shaft Shredders. Recycling systems are evolving rapidly, demanding machines that are not just powerful but also versatile and consistent. At the heart of modern waste processing facilities, Single Shaft Shredders have emerged as an essential tool. These shredders are known for their efficiency, flexibility, and ability to process a wide range of materials with minimal downtime and high throughput. Panchal Plastic Machinery Pvt. Ltd., a trusted Single Shaft Shredders manufacturer, delivers premium-quality shredders tailored for industrial-level recycling.

Originally designed for plastic shredding, Panchal’s mid-range Single Shaft Shredders now serve a much broader purpose, handling materials like wood off-cuts, textiles, industrial film, and more. Their intelligent design — including a robust rotor and swing-pusher in-feed system — helps process even the most challenging materials effortlessly. Let’s explore the five key features that make Panchal’s Single Shaft Shredders a top choice in the recycling world.

One of the standout features of Panchal’s Single Shaft Shredders is the rotor system. Operating at low speeds but with high torque, this rotor mechanism delivers outstanding cutting power while maintaining energy efficiency. This design significantly reduces wear and tear on components, leading to long-lasting performance and reduced maintenance costs.

The rotor is precision-machined, dynamically balanced, and built from high-strength materials. Depending on the material to be shredded — plastic, wood, or textiles — we customize the rotor diameter, cutting profiles, and tooth spacing.

A key contributor to our shredders’ superior throughput is the hydraulic swing-pusher feed mechanism. This system intelligently moves the material toward the rotor, allowing for a uniform and controlled feed rate. Unlike traditional gravity-fed systems, the swing pusher actively prevents material bridging and machine blockages. Combined with the rotor’s cutting efficiency, this setup allows for smoother shredding cycles and higher productivity — exactly what you'd expect from a premium Single Shaft Shredders manufacturer.

Blade wear is an inevitable aspect of shredding operations, especially when processing abrasive or thick materials. Panchal’s Single Shaft Shredders are equipped with easily accessible, reversible cutting blades that can be rotated and reused multiple times before needing replacement. This means lower blade costs, less downtime for maintenance, and consistent shredding performance over time.

Every Panchal Single Shaft Shredder comes integrated with an intelligent PLC-based control system. This user-friendly interface allows operators to monitor shredding performance, adjust speed, manage overloads, and even perform system diagnostics in real-time. These smart controls are essential in reducing manual intervention and increasing overall efficiency — another reason why Panchal is considered a future-ready Single Shaft Shredders manufacturer.

Recycling operations can be noisy and hazardous without the right equipment. Panchal’s Single Shaft Shredders are designed with operator safety and noise reduction in mind. The machines come with complete enclosure guards, emergency stop buttons, interlock switches, and thermal overload protection.

Despite being powerful, the machines run with reduced vibration and minimal noise, making them suitable for indoor and urban facilities. Choosing a trusted Single Shaft Shredders manufacturer means you're also choosing a long-term solution built for safety and sustainability.

Though originally designed for plastic waste, Panchal’s Single Shaft Shredders are widely used across various industries due to their adaptability. These shredders process:

Each application benefits from the shredder’s custom settings, rotor designs, and control features. Industries in furniture, agriculture, packaging, electronics, and automotive recycling are leveraging Panchal's shredders to minimize waste and maximize recovery.

At Panchal Plastic, we believe recycling should be powerful, precise, and profitable. With years of engineering expertise and a deep understanding of the recycling industry, we deliver machines that go beyond expectations. Our Single Shaft Shredders are not only robust and versatile but are backed by one of the most reliable service teams in the country. As a trusted Single Shaft Shredders manufacturer, we focus on building long-term relationships with our clients by offering customized, cost-effective solutions. Our commitment to quality, innovation, and environmental responsibility makes us a preferred partner for industries worldwide.

Single Shaft Shredders are indispensable in the recycling industry, offering unmatched versatility, power, and efficiency. Panchal Plastic’s shredders are a blend of high-tech design and real-world practicality, capable of processing multiple material types with ease. As a leading Single Shaft Shredders manufacturer, Panchal is committed to providing equipment that simplifies recycling, reduces waste volume, and helps businesses grow responsibly. From plastics to wood and textiles, our machines are engineered for optimal performance and long-term reliability, making them the perfect addition to any industrial recycling setup.

Want to boost your recycling output with efficient shredding technology? Call us at +91 7046463391 or email us at info@panchal-plastic.com to learn more about our high-performance Single Shaft Shredders.

Call us on: +91 9824137266 | Mail us on: info@panchal-plastic.com | Or Contact Panchal Plastic today to discover Plastic Recycling Machine requirements with precision and reliability.