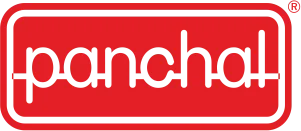

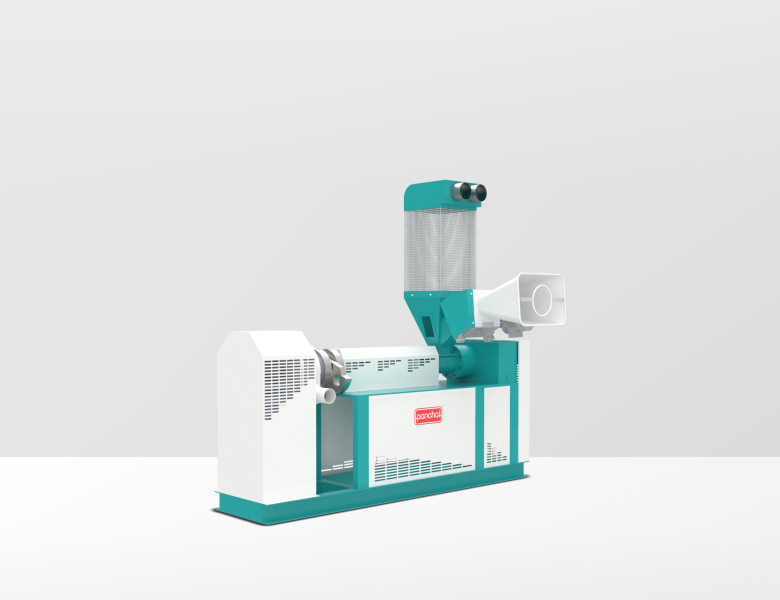

Edge Trim Recycling Plant

The Edge Trim Recycling Machine is engineered specifically for

blown film plants, multilayer/mono-layer extrusion lines, and high-speed film production units

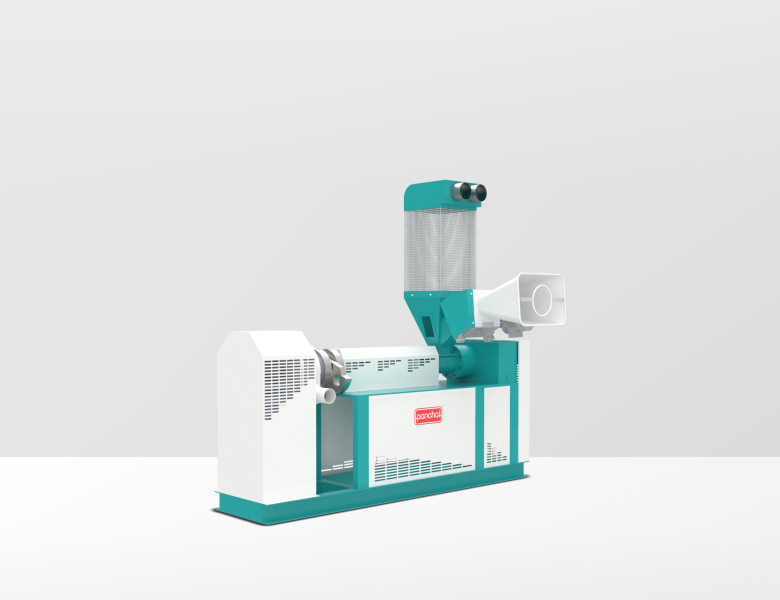

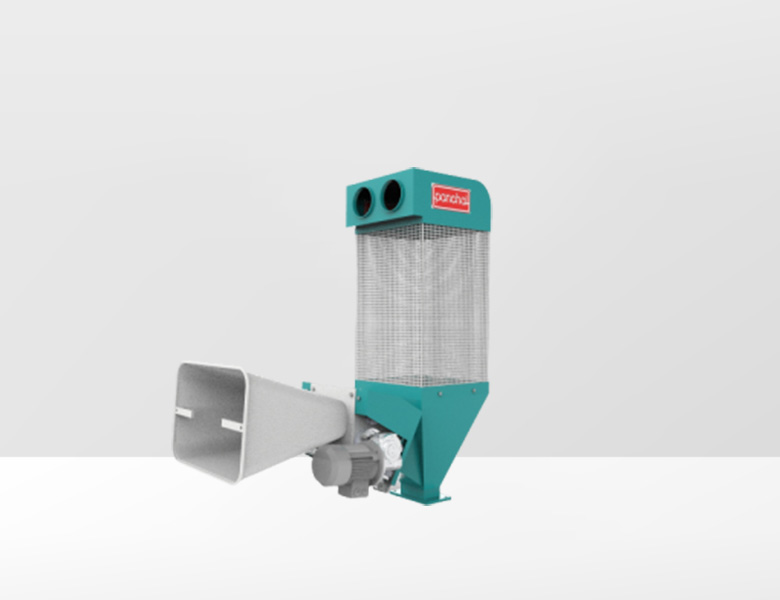

that require continuous inline recycling of edge trim waste. This advanced system instantly collects, cuts, densifies,

and feeds the trim back into the extrusion process, ensuring zero material wastage, consistent granulation, and uninterrupted production flow.

Its compact, open-frame design allows for easy access, low maintenance, and operator-friendly handling, while the AC vector and direct-drive technology ensure

low energy consumption and smooth performance.

The machine supports LDPE, LLDPE, HDPE, and PP films, delivering uniform, high-quality granules suitable

for reuse in the main film line. With plug-and-socket connections for quick servicing, non-obstructive operation, and an air pelletizing system that

eliminates water-cooling issues, it provides a clean, efficient, and cost-saving solution for film manufacturers looking to

recycle trim waste directly on the production floor.

Built for durability, stability, and precision, this system helps reduce raw material costs, improve sustainability, and enhance overall plant productivity.