Description

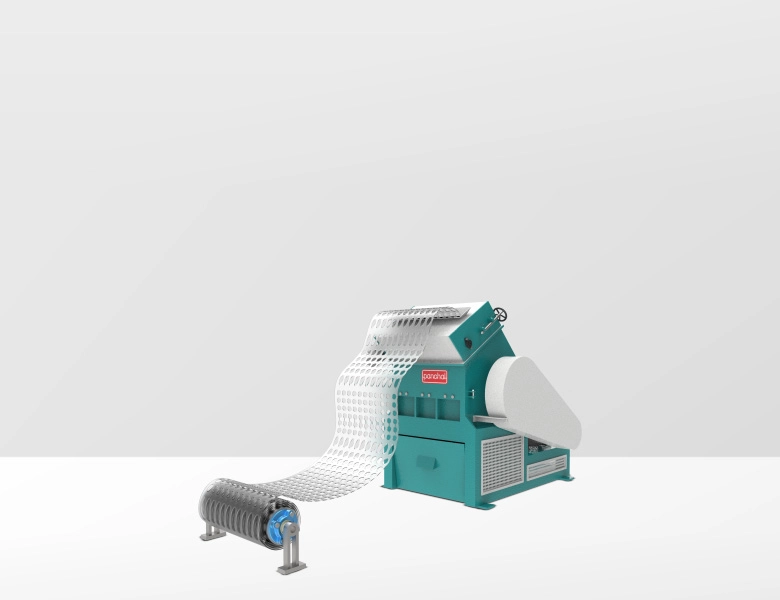

The Thermoforming Series Machine is engineered to deliver high-efficiency grinding and

recycling of sheet and thermoformed sheet waste, offering superior performance for continuous inline and

offline operations. Its advanced rotor assembly features a robust 10-inch diameter rotor

with staggered cutting geometry, ensuring aggressive material intake, uniform size reduction, and minimized

heat generation. Powered by motor capacities of up to 20 HP, the machine is capable of

handling thick, rigid, and high-volume thermoformed parts with ease.

The integrated roller feeding device with an automatic start-stop function guarantees

smooth, synchronized feeding—ideal for connecting directly with thermoforming lines for real-time waste

processing. A curved backwall provides expanded cutting space, allowing the efficient handling of bulky

components without jamming. The cutting chamber incorporates specially engineered 3rd knives and

high-impact blades with deflector wedges, delivering optimal cutting performance and reduced

wear during continuous operation.

Constructed with a heavy-duty welded steel frame, the machine ensures long-term structural

stability and vibration-free performance. Premium D2 steel blades offer exceptional

durability, while the externally mounted bearings protect against contamination and extend service life.

For enhanced convenience, the machine includes an optional tilt-back hopper with auger feed,

available with hydraulic actuation, enabling efficient material handling and easy accessibility.

Maintenance and safety are key design priorities, featuring a jig fixture for precise knife

adjustment outside the cutting chamber, a dropdown screen cradle for rapid

screen changes, and integrated safety interlocks to ensure operator protection during use.

Together, these features make the Thermoforming Series Machine a high-performance, low-maintenance solution

tailored for demanding thermoforming and sheet-processing environments.

Key Highlights

- 10-inch diameter rotor assembly with staggered cutting design for efficient material processing.

- Powerful motor options up to 20 HP for handling thick and rigid thermoformed parts.

- Roller feeding device with automatic start-stop control for smooth and synchronized operation.

- Online integration capability with thermoforming machinery for real-time recycling.

- Curved backwall to accommodate large-volume and bulky sheet waste without clogging.

- Specially engineered 3rd knives and D2 steel blades with deflector wedges for superior cutting efficiency.

- Heavy-duty welded steel construction and vibration-free performance for long-term stability.

- Bearings and housing placed outside the cutting chamber for extended lifespan and easier maintenance.

- Optional tilt-back hopper with auger feed, hydraulic version available for effortless material handling.

- Jig fixture for external knife adjustment, enabling quick and precise setup.

- Safety interlocks and dropdown screen cradle for rapid maintenance and operator protection.