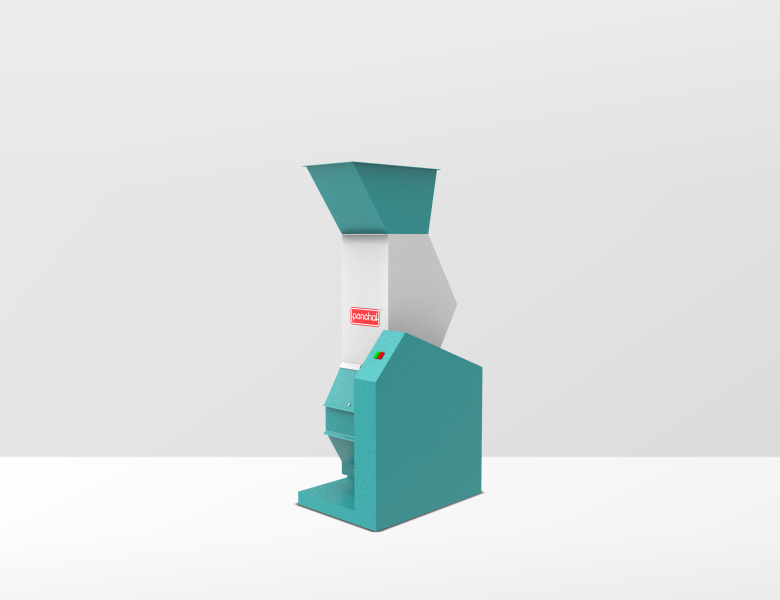

Description

Slow Speed Cutting System

- Staggered rotor

- Tangible Cutting Chamber

- D2 Steel Knives

- Drop down screen cradle

- Tilt Back Soundproofed Hopper

- Low RPM Rotor

- Safety interlock

- Caster Mounted

The Slow Speed Cutting System is engineered for precise and energy-efficient granulation

of sprues, runners, and small injection-molded parts. Its staggered rotor design maximizes cutting

contact, ensuring clean, uniform granules while minimizing dust formation. The D2 steel knives

provide exceptional durability and sharpness retention, reducing the frequency of maintenance and blade

replacement. The machine’s tangible cutting chamber ensures smooth material flow, reducing stress

on the rotor and improving overall cutting efficiency.

The tilt-back soundproofed hopper reduces operational noise significantly, making the system

suitable for use directly beside injection molding machines. The low RPM rotor reduces heat

generation and prevents material degradation, ensuring consistent granule quality. Designed with

operator safety in mind, the built-in safety interlock system prevents access during operation,

while the drop-down screen cradle allows quick and easy screen changes and cleaning.

The entire unit is caster mounted for easy movement, positioning, and integration into different

production environments.

This slow-speed granulator is ideal for on-demand recycling beside the press, reducing waste at the

source and improving overall production efficiency. Its robust construction, low maintenance

requirements, and consistent performance make it an essential tool for industries relying on

high-precision injection molding, small part production, and clean material reprocessing.