Description

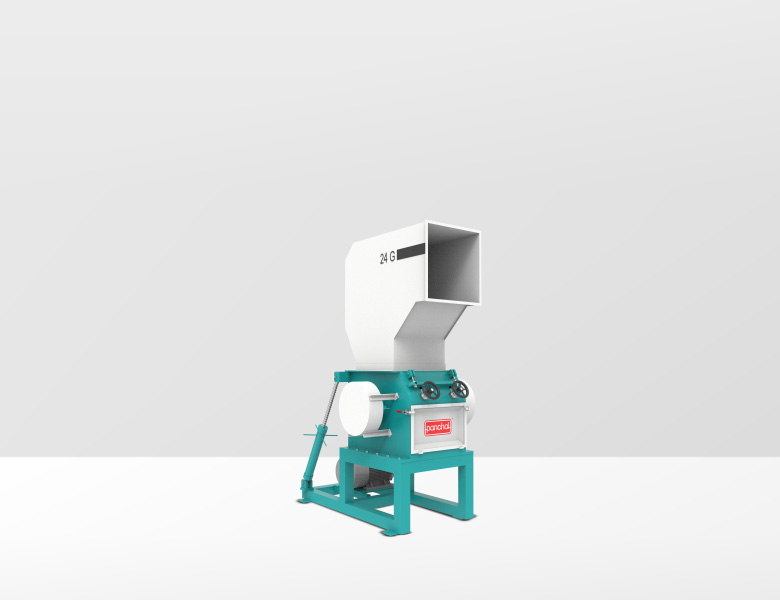

The Film and Sheet Series Machine is engineered specifically to process lightweight, flexible,

and high-volume materials such as thin films, sheets, laminates, rolls, and packaging waste. Built with a

specialized high-efficiency rotor optimized for soft and stretchable polymers, the machine ensures

superior cutting performance while minimizing heat buildup and preventing film wrapping around the rotor.

Its curved backwall design provides additional space for handling bulky, fluffy film materials,

enabling smooth feeding and consistent throughput even during demanding continuous operations.

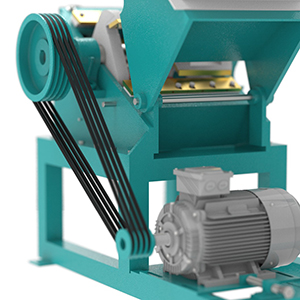

Constructed from heavy-duty welded steel, the system is built for long-term durability and vibration-free

operation. The cutting system uses D2 wear-resistant steel blades, including specially developed 3rd knives

and deflector wedges that enhance film grip, improve cutting efficiency, and maintain uniform particle size.

Heavy-duty bearings positioned outside the cutting chamber ensure protection from dust and contamination,

significantly increasing service life and reducing downtime.

For enhanced cooling and processing stability, the machine offers optional body water cooling, especially

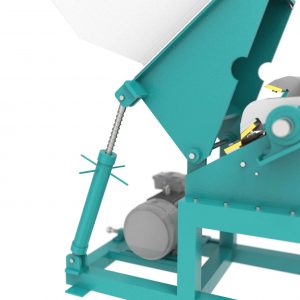

beneficial for heat-sensitive materials. An optional tilt-back hopper with auger feed—hydraulically operated

if required—greatly simplifies material loading and handling for large, voluminous film waste. The system is

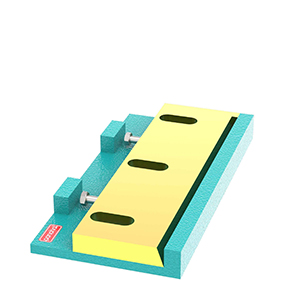

equipped with a precision jig fixture to allow blade adjustments outside the machine, ensuring safe,

accurate, and quick maintenance. Additional safety interlocks, a dropdown screen cradle, and

easy-clean access points guarantee operator safety and streamline service operations.

Key Technical Features:

- Specialized rotor geometry designed for thin films, sheets, and flexible materials.

- Optional water-cooled machine body for heat-sensitive film processing.

- Curved backwall for enhanced volume capacity and smooth material flow.

- Specially engineered 3rd knives and deflector wedges for superior cutting performance.

- High-strength welded steel construction for maximum durability.

- D2 wear-resistant steel blades ensuring extended service life and reduced maintenance.

- Heavy-duty bearings positioned outside the chamber for protection against contamination.

- Optional hydraulic tilt-back hopper with auger for efficient material loading.

- Jig fixture for external and precise blade adjustment and sharpening.

- Integrated safety interlocks for secure operation during maintenance and cleaning.

- Dropdown screen cradle at the front for easy access, quick changeover, and safe handling.

- Optimized airflow management for better cooling and consistent grinding quality.

Engineered for high-volume film and sheet recycling applications, this machine delivers exceptional performance,

reduced energy consumption, and long-term reliability—making it the ideal choice for extrusion plants, flexible

packaging manufacturers, and industrial recycling facilities seeking consistent, high-output processing of

lightweight plastic materials.