Plastic has become part of our everyday routine—think of milk cartons, shampoo bottles, shopping bags, and even plumbing pipes. One of the most used plastics is HDPE (High Density Polyethylene). It's prized for being sturdy and moisture proof, but that also means it sticks around in the environment for a very long time if we don't recycle it.

Recycling HDPE does three big things:

- Keeps plastic out of nature

- Saves energy compared to making new plastic

- Turns old waste into useful material again

To make all this happen, you need the right machines—and that's where Panchal Plastic Machinery shines. They supply every piece of equipment needed to take HDPE from trash back to treasure. Below, you'll find an easy, step by step guide to how HDPE recycling works—and how Panchal's gear makes each step simpler and more reliable.

Why HDPE Recycling Matters

- Environmental health: Discarded HDPE can linger for centuries in landfills or oceans. Recycling stops that.

- Energy savings: Reusing plastic cuts energy use by as much as 80% compared to making HDPE from oil.

- Lower emissions: Recycling puts out far fewer greenhouse gases than fresh production.

- Economic gain: Recycled HDPE pellets are less expensive than virgin resin, and recycling plants create local jobs.

In short, recycling HDPE is good for the planet, for wallets, and for communities.

Step by Step: How HDPE Recycling Works

Gathering & Sorting

First, collected HDPE items—bottles, containers, pipes—are brought to a plant. Workers or machines then sort out anything that isn't HDPE (like PET bottles or metal caps). Clean sorting is crucial: only pure HDPE moves on to the next steps.

Shredding into Flakes

Big pieces of plastic go into a shredder that slices them into coarse bits. Those bits then pass into a grinder (granulator) that chops them into small, roughly uniform flakes. Panchal's shredders feature rugged blades that handle everything from thick drums to rigid crates, while their granulators fine tune the flake size for consistent downstream processing.

Washing Away Contaminants

Flakes still carry labels, glue and leftover product. A wash line—complete with high speed scrubbing drums and spray nozzles—rinses off dirt and adhesive. Next, the flakes enter a water tank where clean HDPE floats and any heavier bits sink and are removed. Panchal's closed loop wash systems recirculate water to cut fresh water use and deliver spotless flakes.

Drying Out the Flakes

Clean flakes go into a spin dryer that flings off water. If any moisture remains, a gentle hot air dryer finishes the job. Thorough drying makes sure the flakes melt evenly in the next phase.

Special Handling for Films & Bags

Thin plastic films and bags can slip through regular shredders. Panchal's Agglomerator cuts and presses these flimsy scraps into small, solid pellets—so even soft, lightweight HDPE scraps can be recycled without clogging the line.

Melting & Pelletizing

Now the flakes (or agglomerated nuggets) feed into an extruder—a machine that heats and turns them into molten plastic. The hot plastic is forced through a die to form long strands. As the strands cool, a cutter slices them into tiny, uniform pellets. Panchal's extruders have sturdy screws and easy change filters to handle recycled material cleanly, and their pelletizers produce smooth, consistent pellets ready for reuse.

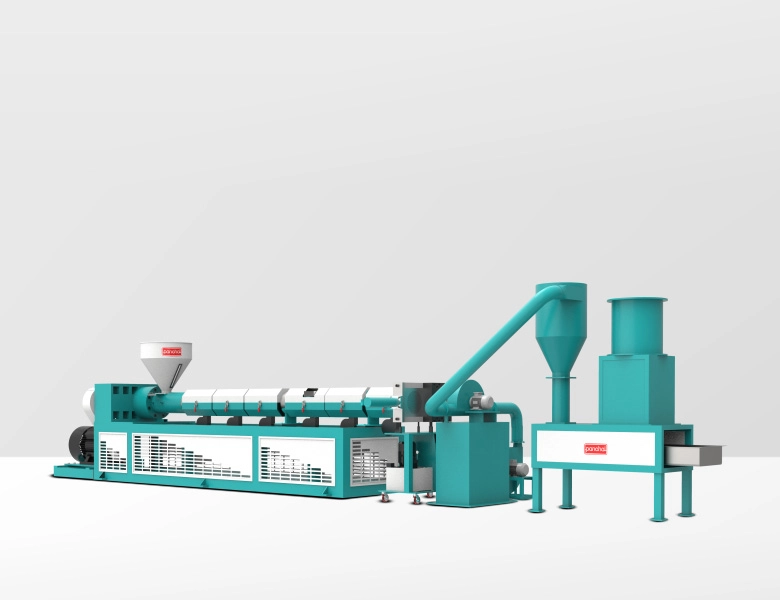

Panchal's Complete Recycling Lines

Panchal doesn't just sell one machine—they provide whole recycling plants. Their typical setup includes:

Granulators

Turn waste into uniform flakes for processing

- Heavy-duty construction

- Adjustable flake size

- Low maintenance design

- High throughput capacity

Washing Line

Remove all contaminants from plastic flakes

- Friction washers

- Sink-float separation

- Closed water loop

- High-pressure rinsing

Centrifugal Spin Dryer

Prepare flakes for extrusion

- Centrifugal drying

- Hot air finishing

- Energy efficient

- Uniform results

Agglomerator

Process film and bag scrap

- Handles lightweight materials

- Prevents line blockages

- Continuous operation

- Low energy consumption

Extruder & Pelletizer

Create uniform recycled pellets

- Precise temperature control

- Easy-change filters

- Strand pelletizing

- High quality output

Why Choose Panchal Machinery?

- Proven Reliability

Sturdy construction and wear resistant parts mean Panchal machines run day in, day out with minimal downtime. - Energy Smart Design

Optimized motors and process flows cut electricity bills and extend machine life. - Water Conservation

Closed circuit wash systems reduce fresh water use, shrinking both water costs and environmental impact. - Scalable & Modular

Start small and grow: add more modules or larger machines as your recycling volume increases. - Easy Operation & Maintenance

User friendly controls, quick access panels, and comprehensive training make sure your team stays productive.

Overcoming Common Recycling Hurdles

- Dirty feedstock: Panchal's multi stage washers eliminate tough grime and adhesives.

- Film blockages: Agglomerator densify films into easy to handle chunks.

- Moisture issues: Two stage drying delivers flakes dry enough for smooth extrusion.

- Mixed materials: Effective sorting and sink float separation keep non HDPE contaminants out.

With these solutions in place, recyclers produce top quality pellets with fewer stops and starts.

The Future of HDPE Recycling

Global demand for recycled HDPE is rising as brands and regulators set tougher recycled content targets. Improved waste collection, advances in sorting technology, and consumer pressure all drive growth. Reliable machinery is key to capturing this opportunity—and Panchal's lines are already running in dozens of countries, helping recyclers meet or exceed these new demands.

In Summary

Recycling HDPE is essential for reducing plastic pollution, saving energy, and building a circular economy. Panchal Plastic Machinery equips recyclers with every machine needed—from shredders and washers to agglomerates and pelletizers. Their energy efficient, water saving, and high reliability designs make HDPE recycling straightforward and profitable.

By turning old plastic into reusable pellets, Panchal's systems support a cleaner planet and a healthier bottom line. If you're ready to step up your HDPE recycling game, Panchal Plastic Machinery has the complete solution.

Our Range of Plastic Recycling Machines

Call us on: +91 9824137266 | Mail us on: info@panchal-plastic.com | Or Contact Panchal Plastic today to discover Plastic Recycling Machine requirements with precision and reliability.