Key Takeaways:

In the dynamic industrial corridors of Vapi, Daman, and Silvassa, sustainability has transitioned from being merely a corporate buzzword to an operational imperative. These manufacturing hubs, renowned for their robust industrial output, now face the critical challenge of plastic waste management. At Panchal Plastic Machinery, we recognize this challenge as an opportunity - an opportunity to transform what was once considered waste into valuable, reusable resources through cutting-edge recycling technology.

The industrial clusters of Vapi, Daman, and Silvassa collectively generate staggering volumes of plastic waste daily. From packaging materials to production scraps, this waste stream represents both an environmental liability and a potential resource. Traditional disposal methods prove increasingly inadequate due to:

This perfect storm of factors makes plastic recycling not just environmentally responsible, but economically essential for forward-thinking manufacturers.

Our industrial recycling solutions address these challenges head-on by converting plastic waste into high-quality raw materials. This transformation delivers multiple competitive advantages:

By recovering and reusing plastic materials, manufacturers can reduce their virgin material purchases by 30-50%, significantly impacting bottom lines.

Our systems help businesses stay ahead of evolving environmental regulations, avoiding potential fines and operational disruptions.

Streamlined waste handling processes free up valuable floor space and improve overall workflow efficiency.

Panchal Plastic Machinery offers a complete ecosystem of industrial-grade recycling equipment, each component engineered for maximum performance:

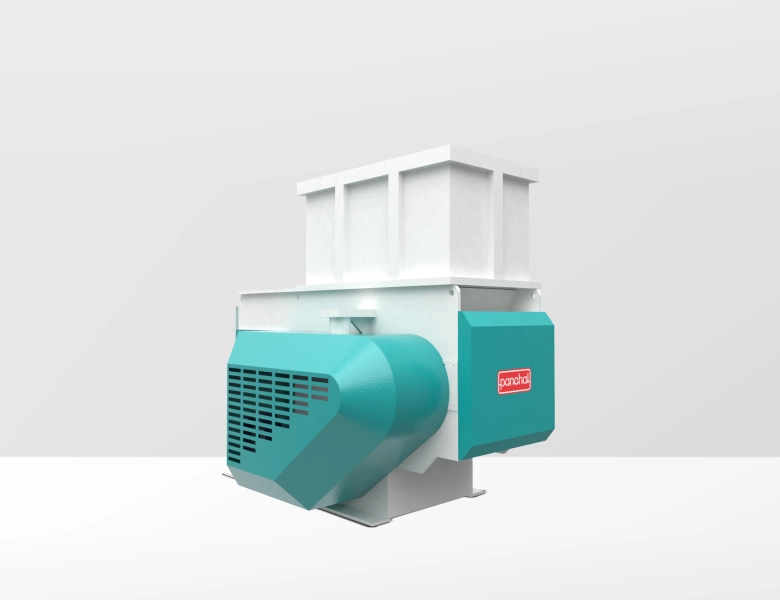

Shredders/Crushers

Shredders/CrushersOur heavy-duty shredders feature hardened steel blades and variable speed controls to process everything from rigid plastic parts to film waste. With capacities ranging from 100kg/hr to 2000kg/hr, these machines reduce bulk materials to optimal sizes for further processing.

Agglomerators/Densifiers

Agglomerators/DensifiersSpecifically designed for LDPE, LLDPE, and HDPE films, our agglomerators use friction heating to transform lightweight materials into dense, easy-to-handle flakes. The integrated dust collection system maintains clean operations while increasing material density 5-8 times.

Grinders/Granulators

Grinders/GranulatorsPrecision-engineered cutting systems produce uniform flakes with options for both wet and dry grinding processes. Soundproof models and automatic screen changers allow for flexible operation in various production environments.

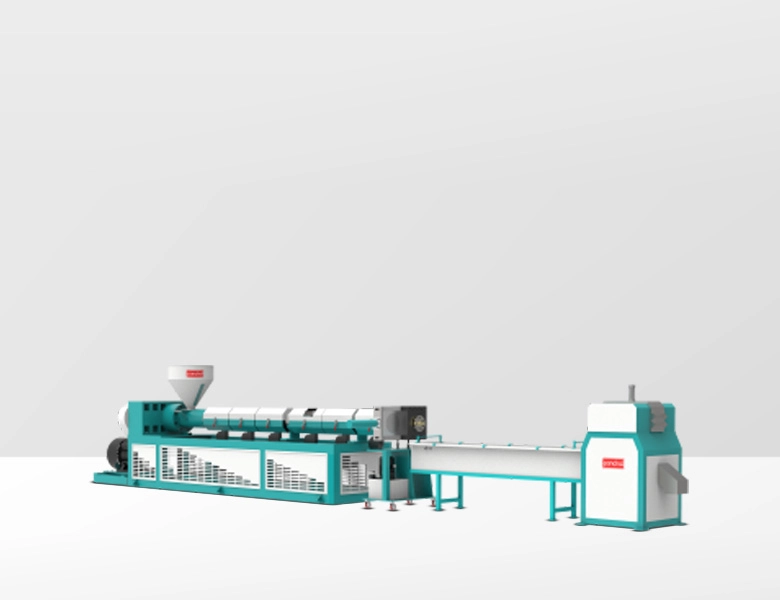

Extruders

ExtrudersAvailable in single or twin-screw configurations, our extruders feature precise temperature control zones and optional filtration systems. They efficiently convert processed plastic into high-purity granules suitable for reintegration into manufacturing processes.

Washing Lines

Washing LinesMulti-stage washing systems remove even stubborn contaminants through a combination of friction washing, float-sink separation, and specialized chemical treatments. Water recycling systems minimize consumption while ensuring thorough cleaning.

Mixers

MixersFrom high-speed intensive mixers to slow-speed tumble blenders, our mixing solutions ensure perfect homogenization of recycled materials with additives or virgin resins, maintaining consistent product quality.

Understanding that each manufacturing operation has unique requirements, we specialize in developing customized recycling systems that address specific challenges:

Complete lines handling post-industrial film waste and trim

Systems optimized for rigid plastic scraps and rejected parts

Solutions for mixed plastic waste streams

Heavy-duty systems for engineering plastics

Our commitment extends far beyond equipment delivery:

Detailed analysis of your waste stream and production requirements

Custom layouts with capacity specifications and ROI projections

Expert supervision and comprehensive testing

Hands-on instruction and complete operational manuals

Local technical assistance and maintenance services

By adopting our recycling solutions, industries in Vapi, Daman, and Silvassa are:

Panchal Plastic Machinery stands ready to partner with industries across Vapi, Daman, and Silvassa in their sustainability journeys. Our comprehensive recycling solutions offer a practical pathway to:

The time for action is now. By implementing these solutions today, forward-thinking manufacturers can secure their competitive position while contributing to a cleaner, more sustainable industrial ecosystem.

Contact our team of recycling experts today to schedule a comprehensive waste assessment and discover how our solutions can be tailored to your specific operational needs.

Get a Free Consultation