In today's world, where environmental conservation is no longer a choice but a necessity, the demand for sustainable and innovative recycling solutions is at an all-time high. PET (Polyethylene Terephthalate) is one of the most used plastics, found in bottles, containers, and packaging across the globe. Unfortunately, improper disposal of PET waste contributes significantly to environmental pollution. But with the rise of advanced recycling technology, this waste can be converted into high-value raw material for reuse. At Panchal Plastic Machinery Pvt. Ltd., we lead this transformation with our cutting-edge PET recycling plant—engineered to deliver quality, performance, and sustainability.

As one of the most recognized PET Bottle Washing Machine Manufacturers in India, we combine engineering expertise with innovation to offer a complete solution for PET waste management. In this explore into the working process, advantages, and why our PET recycling plant is a game-changer in the circular economy.

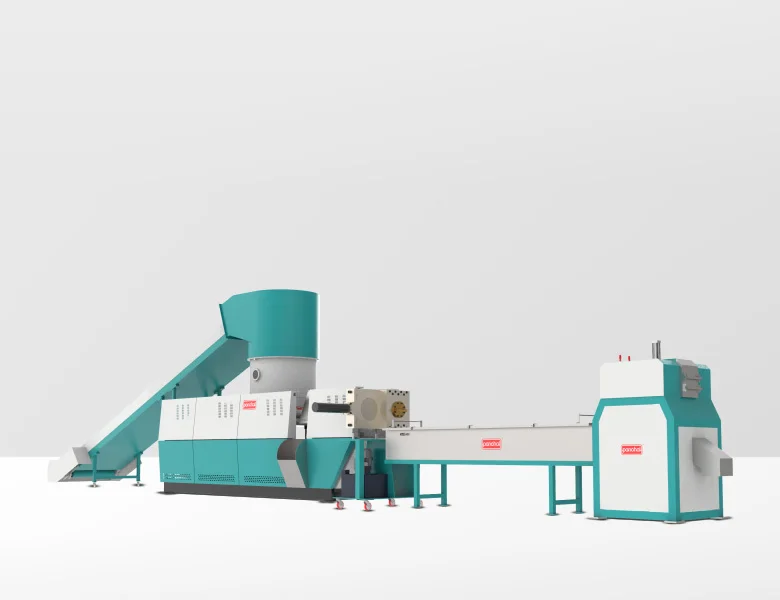

A PET recycling plant is a fully integrated system designed to recover, clean, and reprocess post-consumer PET bottles and containers. The process starts with collection and moves through a series of stages—sorting, washing, grinding, drying, and pelletizing—transforming plastic waste into reusable flakes or pellets that can be used in new products such as textile fibers, food-grade packaging, and strapping.

At Panchal Plastic, our PET recycling lines are designed with precision, keeping in mind the high contamination levels in post-consumer PET waste. That’s why we’ve also gained popularity as one of the most trusted PET Bottle Washing Machine Manufacturers in India. Our machines are known for delivering cleaner output and longer operational life.

Our PET recycling system is a combination of automated modules that carry out different functions:

We believe recycling should be easy, scalable, and cost-effective. Here are the standout features of our PET recycling systems:

With growing demand for recycled PET in international markets, more manufacturers are turning to trusted PET Bottle Washing Machine Manufacturers in India like Panchal Plastic to upgrade their recycling operations.

At Panchal Plastic, we don’t just build machines—we build recycling ecosystems. With years of experience and deep technical expertise, we understand the unique needs of PET recyclers. Our design team, engineering staff, and customer support crew work closely with each client to deliver a system that maximizes efficiency and ROI. As one of the leading PET Bottle Washing Machine Manufacturers in India, we take pride in offering equipment that is durable, cost-effective, and backed by complete technical support. Our commitment to sustainability and innovation helps industries turn waste into wealth—responsibly and profitably.

A PET recycling plant is more than just a setup—it’s a long-term investment in a cleaner planet and a sustainable future. Panchal Plastic stands at the forefront of this green revolution with its advanced technology, efficient design, and unmatched service. As one of the most reputed PET Bottle Washing Machine Manufacturers in India, we deliver more than machines—we deliver value, support, and results. Our plants are already helping industries turn PET waste into reusable material, reducing plastic pollution and opening new avenues for revenue.

Want to turn plastic waste into valuable PET material? call us at +91 7046463391 or email us at info@panchal-plastic.com to learn more about our PET recycling solutions.

Call us on: +91 9824137266 | Mail us on: info@panchal-plastic.com | Or Contact Panchal Plastic today to discover Plastic Recycling Machine requirements with precision and reliability.