Technology

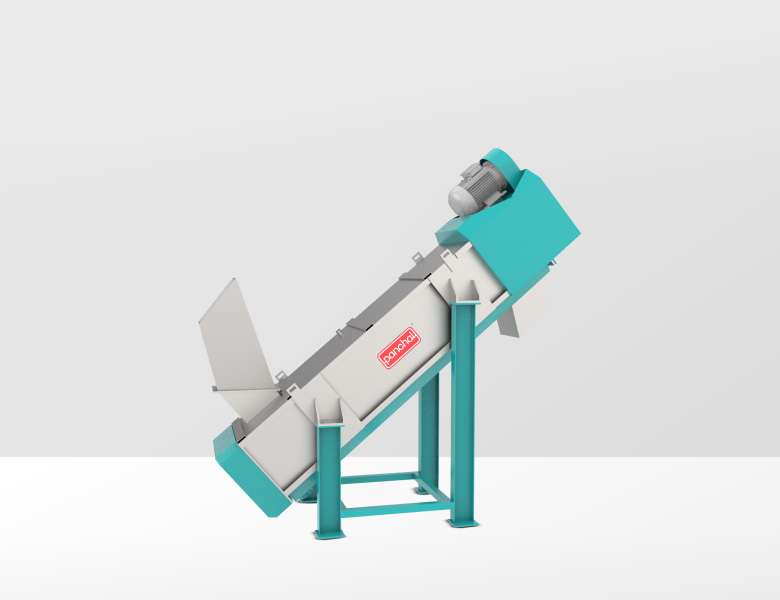

The friction washer is made of a cylindrical trough with an inclined high speed running paddle screw to dewater and clean ground material (film flakes, granules and similar material).

The screw is fixed in the bearing housing by the means of two bearings and enclosed by a stainless steel screen.

The ground material and water are fed from above at the lower end of the trough.

Then the material is washed while being transported to the outlet at the top of the trough.

Fines and water are thrown through the fine screen to the outside while the friction of the high-speed screw cleans the material.

The drain is located at the lower end of the trough.

The screen is automatically cleaned by means of a water-rinsing unit.

| MODEL | PPM-40-150FW | PPM-40-230FW | PPM-70-250FW | PPM-70-450FW |

|---|---|---|---|---|

| Main motor power (KW) | 11 | 22 | 30 | 37 |

| Rotor diameter (mm) | 350 | 350 | 650 | 650 |

| Type | Incline | Incline | Incline | Incline |

| Production Film (kg/hr) | 300 | 700 | 1200 | 1500 |

| Production Flake (kg/hr) | 800 | 2000 | 3000 | 4000 |