Choosing the appropriate Plastic extrusion system: the Expert purchase guide.

Any investment in plastic extrusion technology should be done with keen focus on both technical requirements and functional requirements. This is a detailed guide that discusses some of the essential considerations that manufacturing personalities must make when choosing equipment to meet their production requirements.

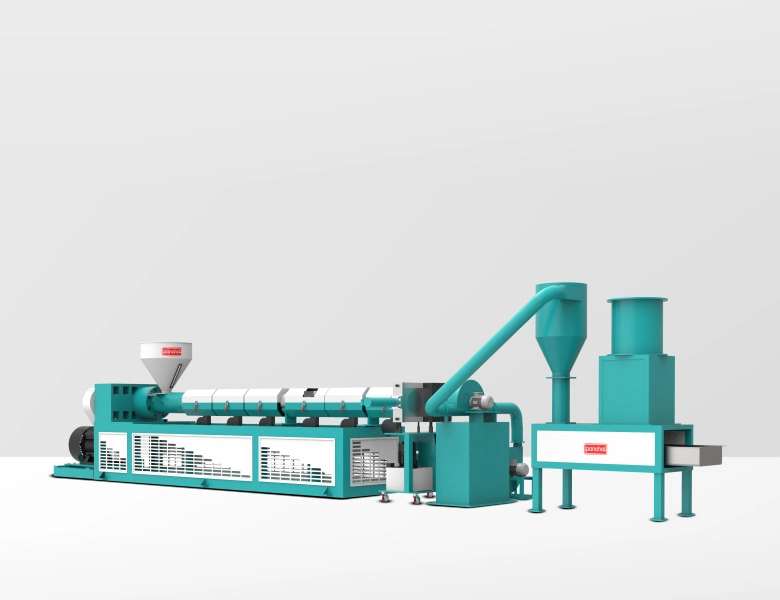

Raw thermoplastic materials are converted to continuous profiles by plastic extrusion, a controlled thermal mechanical process. Plastic feedstock is added to a heated barrel in the system where a finely-designed screw moves the material and melts it. This melt is then compelled into a die of the preferred shape to form the required cross-section and allowed to cool and solidify.

The process allows production of similar profiles continuously, and it is most suitable in producing products ranging between construction and packaging materials.

Extrusion technology has many uses in the manufacturing industries:

PVC profiles are used in the construction industries as window frames, piping, and building components.

Container materials, sheets and films are made by packaging manufacturers.

The automotive suppliers produce seals, trim parts, and shielding.

The manufacturers of consumer goods also manufacture different plastic profiles and special components.

In weighing the extrusion systems, some key factors to weigh include:

Production Requirements

Identify the desired production rate (kg/hour), working schedule and annual production quantity. These are the aspects that have a direct impact on machine size and configuration.

Material Compatibility

Be sure that the system can process whatever polymers you are working with the recycled material or special compound. Various materials demand certain screw design and heat profile.

Technical Specifications

Consider screw design features, drive power, length to diameter ratios and control system capabilities. These factors define the flexibility of the processing and the energy efficiency.

Operational Considerations

Determine footprint needs, utility needs and compatibility with available material handling systems. Think ahead about how it can be expanded and changed in the future.

Purchase price of equipment is just one of the aspects of the overall investment. An overall financial analysis must cover:

Rates of energy consumption and energy efficiency characteristics.

Serviceability and anticipated maintenance time frames.

Dies and calibration equipments tooling.

Labor needs and staffing costs of operation.

projected output and consumption rates.

The appropriate equipment provider entails an evaluation of:

Take advantage of technical support and response.

Installation and commissioning services.

Instruction manuals and training programs.

Maintenance support and spares.

Experience and use of application in the industry.

Equipment integration is successful with:

Preparation of facilities relating to utility connections and material flow.

Extensive safety and process training of operators.

Design of material handling system of the raw materials and finished product.

Maintenance planning and inventory of spares.

Quality control programs and manufacturing record systems.

When choosing the right extrusion technology, it is important to analyze technical needs, financial aspects, and operating needs. With the right equipment investment, the production capabilities could increase dramatically while operational efficiency is improved.

To access more technical specifications or application specific recommendations, please talk to our engineering team to find out more about your specific production needs.

Contact us today to discuss your project requirements and how we can assist you in achieving your production goals.