High-performance equipment designed for processing all types of plastic waste with maximum efficiency and durability

Industry leaders in plastic recycling technology since 1981

Exporting premium recycling solutions to 35+ countries

Trusted by leading plastic manufacturers worldwide

Engineered for performance, built for durability - customized for your specific needs

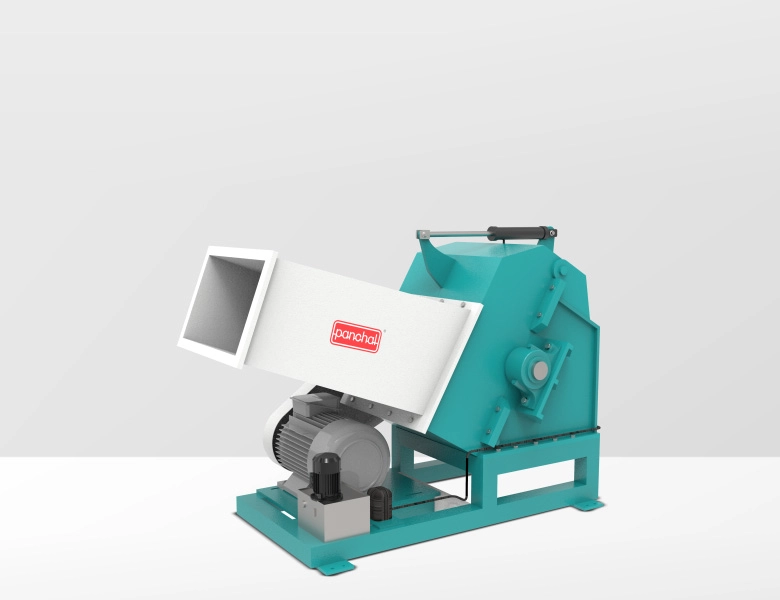

Heavy-duty grinding solution for HDPE, PVC, and PVS pipes/profiles with adjustable output from 20-1000 kg/hr. Features D2 steel blades and multiple feeding options.

Industrial-grade plastic grinder specifically designed for processing blow molding waste and rejects, from small containers to large 200L drums.

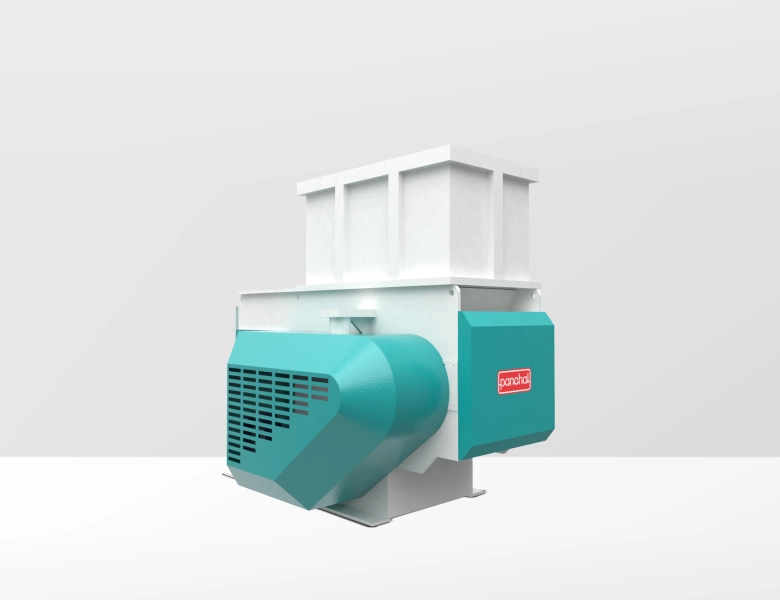

Heavy-duty grinder for thick-walled plastic parts, pipes, and profiles. Features a solid metal rotor and D2 steel knives for efficient processing of bulky materials.

Our single shaft shredder was originally designed for efficient plastic shredding, but its capabilities extend to various materials, including wood off-cuts and textiles. Features remarkable throughput rate with rotor and swing-pusher in-feed system.

Transforms plastic waste into compact cubes for efficient storage and transportation. Processes LDPE, HDPE, PP, woven sacks, and industrial scrap plastic into reusable material with high output rate and low maintenance.

High-speed mixer for uniform blending of virgin material, masterbatch and pigment. Features 304 stainless steel tank, low RPM mixing, automatic timer, and safety bars. Ensures superior color quality for extruder processing.

Compact, energy-efficient system for recycling blown film edge trims. Features AC vector drive, air pelletizing system, and simple operation. Processes multilayer films, roll scrap, and slightly printed materials with minimal degradation.

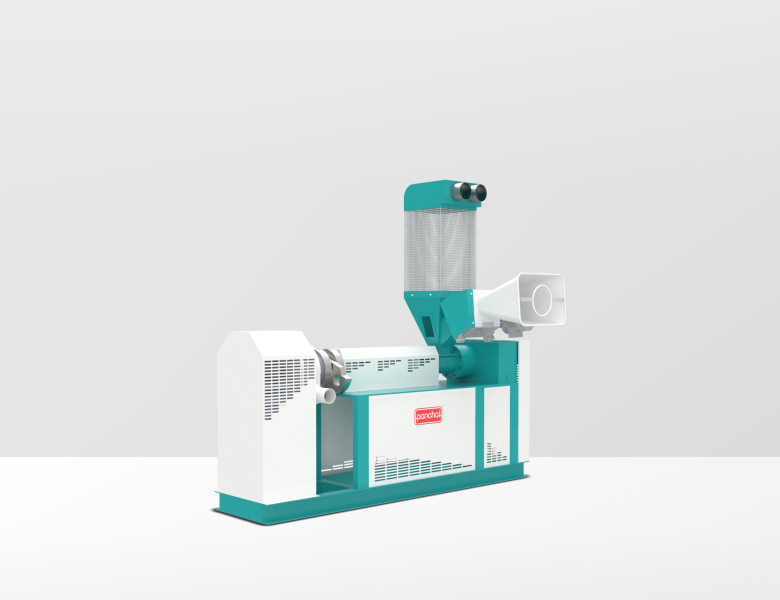

All-in-one system combining cutter compactor and extruder for efficient plastic waste processing. Handles films, sheets, bags, and raffia waste with advanced degassing options. Reduces energy consumption by 30% while producing high-quality recycled pellets.

High-performance extruder with force-feeder system for efficient processing of LLDPE, LDPE, HDPE, PP and other plastics. Features vented extruder, die-face cutter, and hydraulic screen changer for producing virgin-quality granules from various plastic wastes.

Engineered for industrial performance with innovative features

Heavy-duty machines built with premium steel components for 24/7 operation in demanding environments.

Optimized designs deliver 20-30% higher throughput compared to conventional recycling machines.

CNC-machined components and balanced rotors ensure smooth operation and minimal vibration.

Tailored solutions available for specific materials, throughput requirements, and facility layouts.

Join our growing family of satisfied clients worldwide

What industry leaders say about our recycling solutions

Our engineering team will help you select the optimal equipment configuration for your specific material types and production requirements.