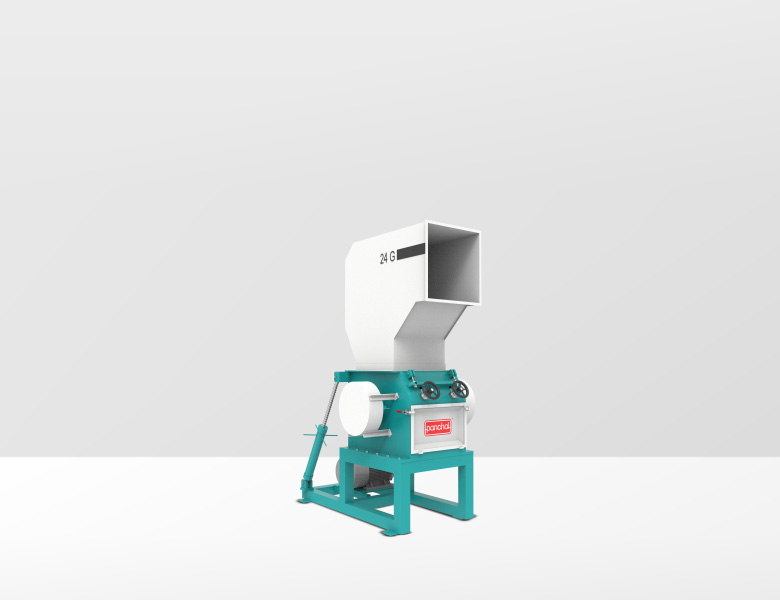

The Plastic Scrap Grinder cuts plastic waste into small pieces for reuse. It’s ideal for factories, recycling plants, and packaging firms. This helps companies save money and reduce waste.

Our industrial-grade plastic scrap grinder is in action.

Key Features of Our Plastic Scrap Grinder

Sturdy Construction

Heavy-duty steel frame for long-lasting use.

- Sharp D2 steel blades cut through tough materials.

- Stable design reduces vibrations during operation.

Easy Material Feeding

- Manual loading for small tasks or automatic feeding for large jobs.

- Suitable for both small shops and large factories.

Special Roller for Thin Plastics

- Roller feeder prevents jamming with thin plastic film.

- Enhanced cutting speed for efficiency.

High Performance

- Capacity ranges from 20 kg to 1,000 kg per hour, depending on the model.

- Produces sharp plastic granules with consistent quality.

Energy-Efficient Operation

- Optimized rotors reduce processing time and energy usage.

- Optional soundproof cover lowers noise levels.

Smart Cutting System

- Precision knives ensure clean cuts.

- Many blade options are available for various materials.

- Built-in dust removal keeps the output clean.

Common Applications

The grinder works with many types of plastic waste, including:

Factory scrap

Solid plastic waste

Plastic film waste

Ejected molded parts

Thick sheets and small chunks

Various other plastic types

Durable Design Features

- Front screen with quick access for inspection

- Manual or hydraulic removable hopper options

- Quick blade changing system

- Safety locks for accident prevention

- No overheating even during long operation hours

Technical Highlights

- Motor Power: 5HP to 50HP options

- Blade Material: Premium D2 tool steel

- Cutting Chamber: Hardened steel construction

- Control Panel: User-friendly interface

- Safety Features: Emergency stop, overload protection

Technical Specifications

- Capacity: 20 - 1,000 kg/h

- Cage: Heavily welded steel

- Blades: D2 tool steel

- Rotor: Optimal and balanced design

- Noise Control: Optional soundproof cover

- Cooling: Optional water-cooling system

- Operation: Simple and straightforward

- Durability: Long-lasting construction

Key Benefits

- Reduces waste sent to landfills

- Saves money through plastic recycling

- Energy efficient per kilogram processed

- Minimizes downtime for faster operation.

- Consistent output quality

- Simple maintenance and operation

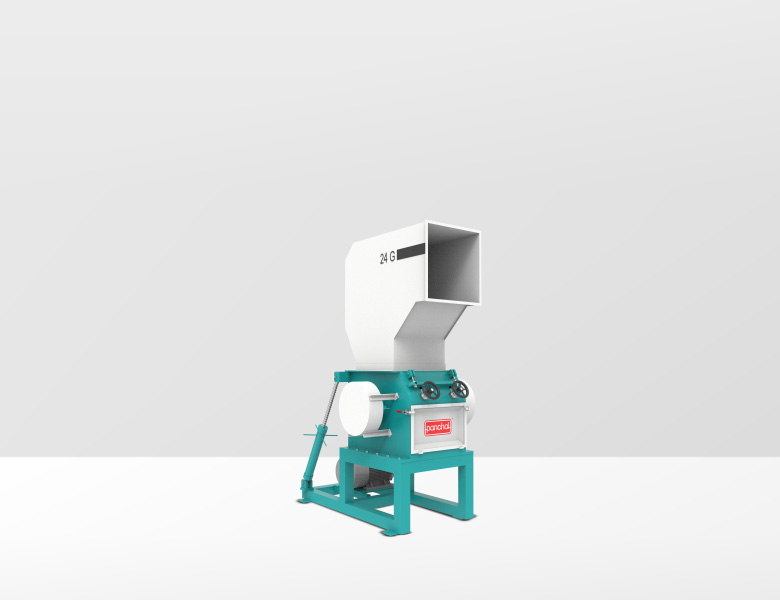

Why Choose Our Plastic Scrap Grinder?

This machine is cost-effective, durable, and easy to use. It suits small workshops and large operations, with options to upgrade as your needs grow.

Our Plastic Scrap Grinder in a typical factory setting, demonstrating its robust performance.

Operational Advantages

- Low maintenance requirements

- Easy to operate with minimal training

- Quick changeover between materials

- Minimal floor space required

Business Benefits

- Fast return on investment

- Reduces raw material costs

- Improves environmental compliance

- Enhances sustainability credentials

Ready to Transform Your Plastic Waste?

Get in touch with our experts to learn more about our Plastic Scrap Grinder and how it can benefit your operations.

Contact Us Todayor call us at +91 7046463391