Recycling of plastic is no longer a choice, it is now a compulsion to the industries that desire to save money, minimize wastage and contribute to sustainability. One of the most common plastics that are employed in the manufacturing industry is HDPE (High-Density Polyethylene).

It is long-lasting, strong and in use in products like pipes, tanks, containers as well as bottles and industrial parts. Even though HDPE has numerous benefits in manufacturing, it poses serious problems with regard to recycling of plastic purgings and lumps.

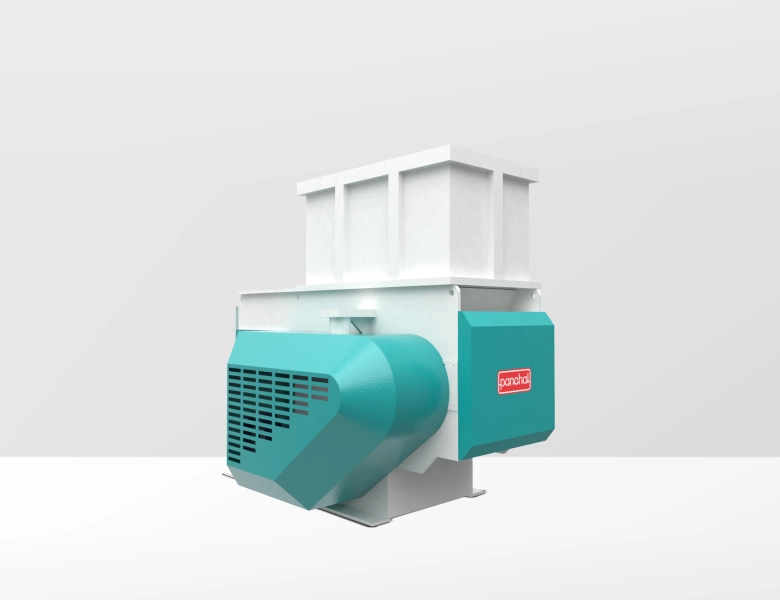

These lumps are formed in procedures such as injection molding, blow molding or extrusion, when the solidified melted plastic is irregularly formed. They tend to be massive, thick and extremely difficult to dismantle. Attempts to use HDPE lumps in regular machines are prone to failure, loss of materials and accidents. The Single Shaft Shredder of Panchal Plastic Machinery is the appropriate solution in this case.

HDPE lumps and purging's are not similar to a normal plastic scrap, including bottles, films, or little pieces.

They are: Bulky and Oversized - Since they are large, they can hardly be fed on regular grinders. Abnormal Shape - Unlike homogeneous scrap, lumps are irregular and unforeseeable and, as a result, jam frequently. Thick and Hard - HDPE lumps are dense, thick and hard, which exerted additional pressure on machines.

Constant Interruptions of Machines - Traditional crushers/ grinders clog or overload. Wasting of Valuable Materials - When the lumps are not recycled, the industries waste raw materials that are reusable. Increased Costs - Downtime, repairs and wastage of resources adds to the total cost of recycling. Safety Hazards - Manual efforts of cutting or breaking lumps are hazardous to workers. The thing is that it is so, HDPE lumps cannot be treated properly without the help of specialized machine.

A Single Shaft Shredder is a shredder that is designed to contain big, rough, and huge plastic waste such as HDPE lumps and purgings. It does not overheat or produce a lot of dust like regular grinders due to high torque at low speed meaning that it is able to cut through dense material.

Feeding- The lump is loaded into the hopper of the shredder. Hydraulic Pusher - This is a powerful hydraulic ram which forces the material to the rotor. Cutting Rotor - The rotor is equipped with heavy duty blades that cut the lump in smaller flakes. Screen Filtering - The flakes are filtered through a screen and this guarantees consistency in size to be processed further. This is done in a slurry format which reduces large HDPE lumps into manageable uniform flakes that are easy to wash, granulate, or directly extruded and compounded.

The Single Shaft Shredder of Panchal Plastic Machinery is unique in the sense that it is designed according to industrial requirements. Heavy-Duty Rotor and Blades - This product is made of wear-resistant steel to slice hard lumps. Hydraulic Feeding System - Forces material into the cutting chamber in a smooth manner without getting stuck. Low Speed, High Torque - Is a reduction in dust, noise and energy consumption with a high cutting force. Adjustable Output Size - Displays of various hole sizes permit a flake size to be controlled. Safety Interlocks - Stops accidents on the part of the operators. Durable Construction- The construction is long lasting with low maintenance, even when used all the time.

This leads to:

Breakage of Extruders and Granulators - Large lumps overpower down stream machines. Irregularity of Output - Inequal feedstock will not produce good quality granules or pellets. Wasted Time - Lumps that are manually cut into smaller pieces take hours to be cut by the workers.

With the help of a Single Shaft Shredder, industries will have the opportunity to: Guard bottom machines - Flakes are the only uniform ones to be fed to granulators or extruders. Optimize recycling - Recycling of consistent feedstock results in more output. Get back more raw material - There is no need to throw away lumps as scrap which can no longer be used. Economize - Less down time, maintenance and effort.

One should be aware of the dangers of not implementing a shredder in the recycling process:

Machine Downtime - Each time a grinder becomes jammed or a blade is broken, the production is stopped. Unnoticed Expenses - Repair expenses, wasted energy and lost raw materials are all taking a toll on profits. Workers Safety Problems - Lump handling by hand is usually a source of accidents. Environmental Impact - The disposed of lumps are not recycled but form landfill waste. Concisely, evading a shredder might appear as a way of saving money in the short run, but it causes greater issues in the long-term.

Panchal Plastic Machinery is over 40 years old in manufacturing of recycling machines. India and the world have put their trust in our Single shaft shredders due to their reliability and performance. Why Choose Panchal? Demonstrated experience - 20 years of serving the recycling sector. Tailor Made Solutions - Waste maximum and capacity machines. Quality Assurance- Rugged construction to last long.

Sustainability Focus - Assisting industries to minimize the amount of plastic waste and recycle useful resources. In investing in the shredder made by Panchal, you are not only purchasing a machine but getting a safer, smoother and more sustainable way of recycling.

Although they are intended to shred HDPE lumps, Single Shaft Shredders by Panchal are flexible.

They can also process: Plastic purging's Rigid pipes and profiles Blow molding waste Industrial rejects Packaging waste This renders them a suitable option to the industries that are involved in processing various recycling challenges of plastics.

The recycling of HDPE plastic lumps is considered as one of the most difficult items in plastic industry. Common machines are not able to cope with the density and irregularity of the lumps and are prone to frequent failures, wastage of resources, and even safety risks. The solution is Single Shaft Shredder by Panchal Plastic Machinery. It reduces thick lumps to homogenous flakes, and preserves downstream equipment and keeps the recycling processes in a steady course. Investing in a shredder is not a choice to industries who are determined to make cost savings, efficient, and environmentally friendly but it must be a necessity. Panchal and his technologically advanced skills make the recycling of HDPE lump less dangerous, less problematic, and much more lucrative.

Make decisions well now, or pay more and less efficiently tomorrow.

Call us on: +91 9824137266 | Mail us on: info@panchal-plastic.com | Or Contact Panchal Plastic today to discover Plastic Recycling Machine requirements with precision and reliability.