Panchal Plastic Machinery Pvt. Ltd. is a leading manufacturer of Wet Grinding Machine. In the fight against plastic waste, recycling plays a critical role in protecting the environment and promoting sustainable industrial practices. Among the many innovative technologies supporting this mission, wet grinding machines are one of the most powerful and efficient tools in the plastic recycling process. These machines offer unmatched precision and productivity, especially in preparing plastic materials for reuse. But what exactly do wet grinding machines do, and why are they such an integral part of plastic recycling?

In this complete guide we’ll explore everything you need to know about wet grinding machines, their function, benefits, impact on recycling efficiency, and why Panchal Plastic is a trusted manufacturer in this space.

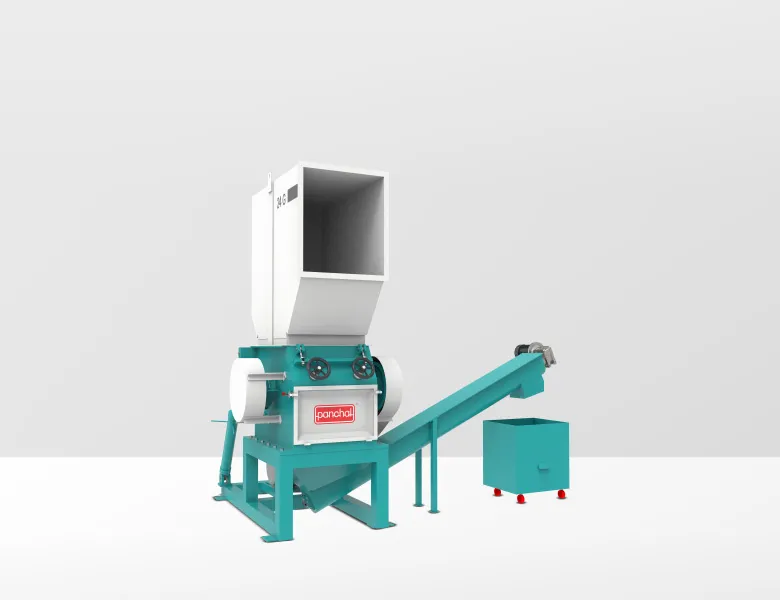

A wet grinding machine is a specialized equipment used to reduce the size of plastic waste material while simultaneously using water as a coolant and lubricant. The water keeps both the machine and the plastic material from overheating, which leads to a smoother grinding process and a cleaner final product.

These machines are designed to process a wide variety of plastics such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and other polymers. Unlike dry grinders, wet grinding machines use water to soften and flush out contaminants during the grinding stage. This makes them highly effective for materials that need cleaning and precision cutting.

The operation of a wet grinding machine is straightforward yet incredibly efficient:

This process not only prepares plastic for recycling but also reduces contamination and material degradation.

Plastic waste collected from various sources often contains dirt, oils, adhesives, and other impurities. Processing such materials without cleaning them would reduce the quality and usability of the recycled plastic. That’s where wet grinding machines play an important role.

By integrating wet grinding machines into a recycling line, plastic manufacturers and recyclers can maintain product quality and increase processing speed.

Let’s break down the major advantages of using wet grinding machines in the recycling industry:

Wet grinding machines are used across various recycling and manufacturing applications. Some of the most common use cases include:

Whether you're operating a full-scale recycling plant or a specialized production unit, integrating wet grinding machines can greatly enhance your operation's effectiveness.

PET (Polyethylene Terephthalate) bottles are among the most recycled plastics globally. However, they often come with labels, adhesives, caps, and residue from beverages. Cleaning is a vital part of recycling PET efficiently, and wet grinding machines offer the best way to achieve this.

With our PET recycling lines, the material goes through several steps — and the wet grinding machine sits at the heart of it. It breaks the bottles into flakes, while removing dirt and impurities, leading to a cleaner and more usable product. This makes Panchal Plastic a trusted supplier of high-quality PET recycling plants equipped with top-tier wet grinding machines.

At Panchal Plastic, we have over 40 years of experience in developing high-quality, technologically advanced recycling machines. We are not just a manufacturer — we are solution providers who understand your challenges and deliver equipment that solves them. Our wet grinding machines are known for their innovation, reliability, and user-focused design. From small-scale operations to large recycling plants, our machines meet the needs of every customer segment. We use only the finest components, backed by superior engineering, to make machines that last and perform under pressure.

Wet grinding machines are more than just a piece of equipment — they are a meaningful change in the plastic recycling world. From cleaning to grinding, these machines offer a dual function that enhances efficiency, reduces contamination, and delivers a high-quality output ready for reuse. For recyclers and manufacturers aiming to improve their process, wet grinding machines are a smart, sustainable investment.

Choosing the right equipment is important, and with Panchal Plastic, you are guaranteed machinery that delivers real value and long-term reliability.

For more information about wet grinding machines in plastic recycling, call us at +91 7046463391 or email us at info@panchal-plastic.com.