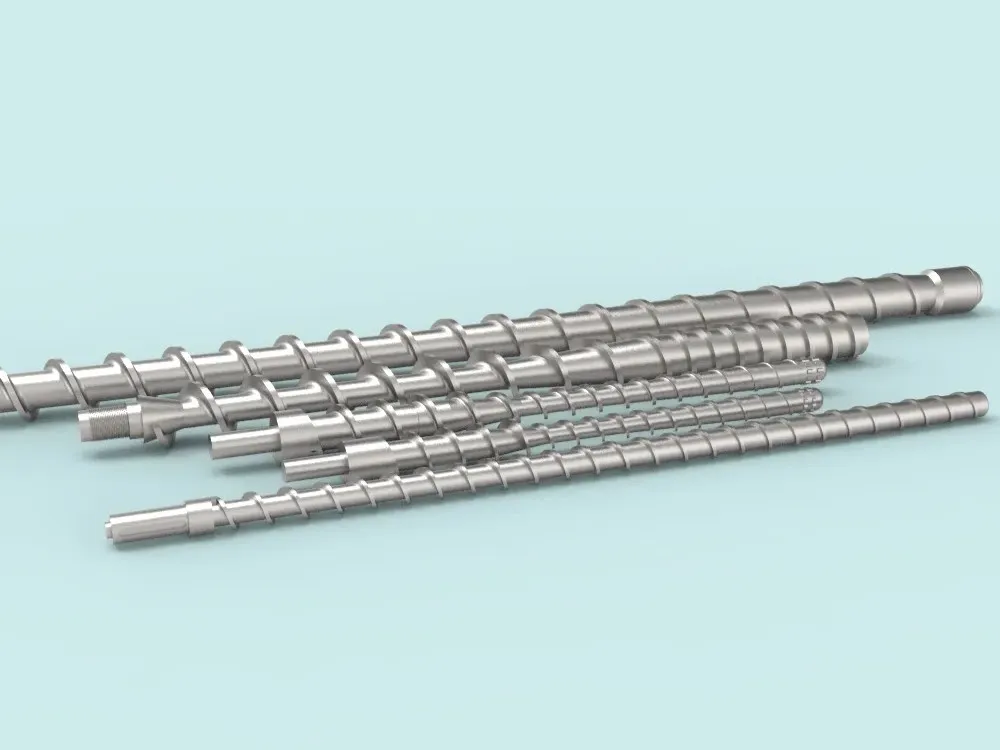

Panchal Plastic Machinery Pvt. Ltd. is a leading manufacturer of Single Screw Barrel. In the fast-paced and environmentally conscious world of plastic recycling, the efficiency of your machinery directly affects your bottom line. Among the many components that make up a reliable recycling system, the single screw barrel plays an essential role. It may look like a simple metal shaft with helical grooves, but its engineering, precision, and performance are what drive high-quality plastic reprocessing. At Panchal Plastic, our advanced screw barrel designs have positioned us as one of the most trusted Single Screw Barrel Manufacturers in India and Single Screw Barrel Manufacturers in Gujarat.

In this, we will explore what makes the single screw barrel so important in recycling, what sets Panchal Plastic apart in manufacturing these components, and how our screw barrels support consistent, high-output recycling systems.

The single screw barrel is at the heart of many plastic processing machines, especially extruders. It is responsible for melting, mixing, and conveying plastic material along the barrel using heat and pressure. The screw rotates inside a heated barrel, driving plastic granules forward where they are melted and homogenized for further processing.

Without a professionally designed screw barrel, the entire recycling process can suffer. Material may not melt evenly, leading to defects, or output may drop due to inefficient mixing. This is why companies around the world rely on top-quality Single Screw Barrel Manufacturers in India to deliver components that keep their operations running smoothly.

A well-designed screw barrel directly influences the following:

This is why Panchal Plastic, as one of the most innovative Single Screw Barrel Manufacturers in Gujarat, puts significant R&D into screw design and metallurgy to meet a wide range of recycling demands.

At Panchal Plastic, we manufacture screw barrels that are engineered for performance, durability, and consistency. Here's what sets our products apart:

Panchal’s single screw barrels are used in a wide range of recycling setups, including:

They are compatible with both virgin and post-consumer recycled plastics, making them ideal for blending and reprocessing. With our expertise as one of the leading Single Screw Barrel Manufacturers in Gujarat, we’ve supplied barrels that have revolutionized plastic waste handling in various industries.

At Panchal Plastic, we believe that the strength of a recycling system lies in the strength of its core components. As leading Single Screw Barrel Manufacturers in Gujarat and among the most trusted Single Screw Barrel Manufacturers in India, we bring unmatched quality, innovation, and customer support. With decades of experience in plastic machinery, we understand recycling from the inside out. We customize every screw barrel for specific applications, use high-performance materials, and back it with expert service and technical support. Our goal is to give our clients the tools they need to recycle smarter and succeed in a circular economy.

The single screw barrel plays an important role in maintaining the reliability and efficiency of recycling systems. A high-quality screw barrel can significantly improve melting, mixing, and material output—leading to higher returns and lower waste. Panchal Plastic stands out among Single Screw Barrel Manufacturers in India for delivering durable, efficient, and customized screw barrels designed to meet the challenges of modern plastic recycling. Whether you are upgrading your extruder or building a new line, our screw barrels are the solution your system needs to succeed.

For Learn how Panchal’s single screw barrels can strengthen your recycling systems, call us at +91 7046463391 or email us at info@panchal-plastic.com today—reliable recycling starts here.

Call us on: +91 9824137266 | Mail us on: info@panchal-plastic.com | Or Contact Panchal Plastic today to discover Plastic Recycling Machine requirements with precision and reliability.